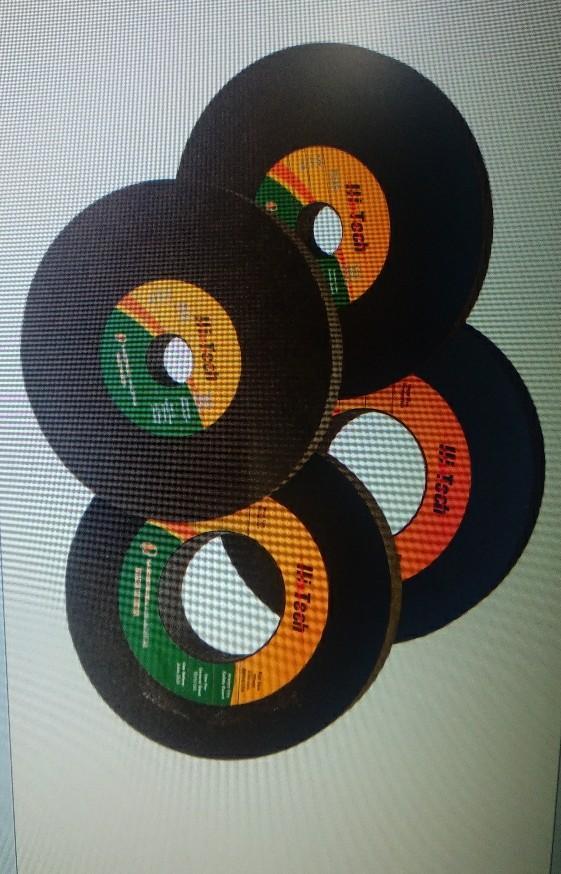

Industrial Grinding Wheels

Price 2500.0 INR/ Box

Industrial Grinding Wheels Specification

- Shape

- Round

- Usage

- NA

- Size

- 300x40, 500x65x203.2mm A163

- Height

- Inch (in)

- Rolls Size

- Standard

- Color

- Black

Industrial Grinding Wheels Trade Information

- Minimum Order Quantity

- 50 Number

- FOB Port

- Transport

- Supply Ability

- 10000 Per Month

- Delivery Time

- 1-7 Days

- Sample Available

- No

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- corrugated boxes

- Main Domestic Market

- All India

- Certifications

- Product Certification

About Industrial Grinding Wheels

These wheels are used in automotive ,ship building, steel fabrication industries and as well as in foundries, forging industries for cleaning and surface of casting , blooms , removal of gates and risers and steel mills fir heavy stock removal , surface correction of billet for smoothening of weld seams.

SPECIFICATION

|

Material |

Aluminium Oxide |

|

Color |

Brown |

|

Brand |

Hi-tech |

|

Shape |

Round |

Robust Construction for Industrial Demands

Our grinding wheels are manufactured with high-strength abrasive materials, ensuring they can withstand rigorous industrial usage. Designed for extended operational life, these wheels provide consistent grinding performance and optimal efficiency in production environments. The precisely engineered dimensions guarantee seamless fitment for a variety of industrial machines, making them an ideal choice for manufacturers, exporters, and suppliers seeking superior quality products.

Customizable Sizes and Versatility

Available in multiple size configurations, such as 300x40 mm and 500x65x203.2 mm (A163), our round grinding wheels accommodate a broad range of applications. From metal fabrication to tool sharpening, their adaptability makes them essential in industries requiring exacting standards. Whatever your grinding requirements, these wheels can be seamlessly integrated into your existing operations.

FAQs of Industrial Grinding Wheels:

Q: How should industrial grinding wheels in the size range of 300x40 and 500x65x203.2 mm be properly mounted for use?

A: Industrial grinding wheels of these sizes should be mounted onto compatible grinding machines following the manufacturers safety guidelines. Ensure the wheel fits securely on the spindle, and always check for cracks or damage prior to installation. Proper mounting helps maintain stability and safety during operation.Q: What materials are these grinding wheels designed to process?

A: While the specific application depends on the abrasive type (A163), these grinding wheels are generally suitable for a range of materials, including steel, cast iron, and various metals. Their robust design supports both rough grinding and precision finishing tasks.Q: When is it advisable to replace an industrial grinding wheel?

A: A grinding wheel should be replaced if it shows signs of excess wear, visible damage, or imbalance. Regular inspection ensures the tool operates safely and efficiently, preventing accidents and maintaining the integrity of your industrial processes.Q: Where can I source these industrial grinding wheels?

A: These grinding wheels are manufactured, supplied, and exported directly from India. As a reliable supplier, we cater to both domestic and global markets, ensuring prompt delivery and adherence to international quality standards.Q: What is the manufacturing process for these industrial grinding wheels?

A: The wheels are produced using high-grade abrasive materials, molded under high pressure and heat, ensuring durability and consistent abrasive properties. Strict quality control measures are implemented throughout the process to guarantee product performance.Q: How can these grinding wheels benefit industrial users?

A: Industrial users benefit from these wheels longevity, precision, and reliability, resulting in reduced downtime, improved productivity, and cost savings. Their versatile sizes offer compatibility with various machines and applications.Q: What precautions should be observed during the use of industrial grinding wheels?

A: Always wear appropriate personal protective equipment, including eye protection, gloves, and dust masks. Verify that the wheel is undamaged and run a test before full operation. Adhering to these precautions enhances worker safety and equipment longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Wheels Category

Scraps Glass Grinding Wheels

Price 12 INR / Piece

Minimum Order Quantity : 400 Pieces

Shape : ROUND

Hardness : NA

Color : Black

Hitech Swing frame wheel

Price 2000.0 INR

Minimum Order Quantity : 2

Shape : Round

Material : Premium quality aluminium oxide

Hardness : Medium to hard

Abrasive Grinding Wheels

Price 12 INR / Piece

Minimum Order Quantity : 25 Pieces

Shape : Flat, Cylindrical, Cup

Material : Aluminum Oxide, Silicon Carbide

Hardness : R (Medium Hard) to Z (Very Hard)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese