Thin Cut off Wheels

Price 15 INR/ Piece

MOQ : 25 Pieces

Thin Cut off Wheels Specification

- Cutting Force

- Low

- Coating Type

- Reinforced

- Operation Type

- Rotary

- Cutting Capacity

- Suitable for Small and Medium Profiles

- Cutting Accuracy

- Precise Thin Cuts

- Operate Method

- Handheld/Automatic

- Cutter Type

- Thin Cut-Off

- Coating

- Resin Bonded

- Hardness

- Medium to Hard

- BladeSize

- 0.8 mm to 2.0 mm (Thickness)

- Features

- Fast Cutting, Minimal Burr, High Performance, Long Life

- Shape

- Flat (Disc)

- Machine Type

- Angle Grinder, Cut-Off Machine

- Cutting Speed

- High (up to 80 m/s)

- Tool Type

- Cut Off Wheel

- Material

- Abrasive Alumina Oxide

- Diameter

- 100 mm to 180 mm

- Processing Type

- Dry & Wet Cutting

Thin Cut off Wheels Trade Information

- Minimum Order Quantity

- 25 Pieces

- FOB Port

- NA

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1-7 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- corrugated Boxes

- Main Domestic Market

- All India

About Thin Cut off Wheels

Application: Excellent and economical choice for Cutting/parting of ferrous nun ferrous bars, pipes, angles, sheet metals, rods and sections.

Product details

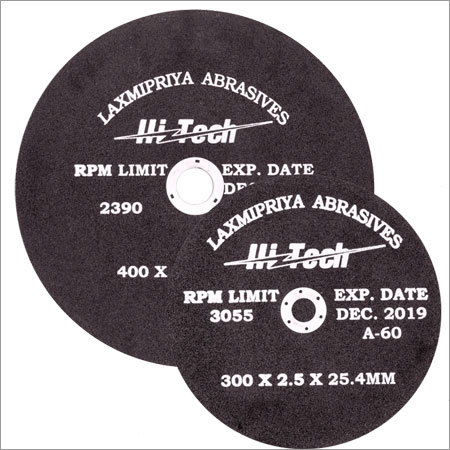

Thickness | 1.2 mm |

Size | 223 x 3 x 22.23 mm |

Shape | Round |

Speed | 6800 rpm |

Abrasive | Cutting Wheel |

Packaging Type | Box |

Color | Black |

Material | Aluminium Oxide |

Brand | Hi-Tech |

Advanced Abrasive Technology

Built with abrasive alumina oxide and reinforced with double mesh fiber, these thin cut off wheels provide outstanding durability and cutting precision. The synthetic resin bond ensures steady performance and consistent hardness while minimizing cutter wear. Designed for high RPM operations, these discs excel in professional metalworking tasks where reliability and output quality matter.

Versatile Applications

Our thin cut off wheels are purpose-built for cutting a variety of metals, from stainless steel to mild steel and other alloys. With their adaptable thickness and range of diameters, they accommodate both small and medium-profile workpieces. Suitable for both dry and wet cutting, they guarantee superior results when used with angle grinders or rotary cut-off machines.

Safe and Reliable Performance

Complying with EN12413 and ISO 9001 standards, these cut off wheels ensure a safe and stable cutting process. With their long shelf life of two years when stored in cool, dry conditions, users can expect consistent performance and minimal risk. The resin bonded, reinforced design reduces breakage and delivers reliable, precise thin cuts for professional use.

FAQs of Thin Cut off Wheels:

Q: How should thin cut off wheels be stored to maximize their shelf life?

A: To maintain the full two-year shelf life, store the cut off wheels in a dry, cool environment away from moisture and direct sunlight. Proper storage helps preserve bonding strength and wheel integrity, keeping them ready for optimal, safe performance.Q: What materials can these thin cut off wheels cut effectively?

A: These wheels are designed for fast, accurate cutting of stainless steel, mild steel, various metals, and alloys. Their abrasive grain and resin bond combination ensure efficient cutting with minimal burrs or deformation of the workpiece.Q: When is it best to use the 0.8 mm or 1.0 mm thick wheels compared to 1.2 mm ones?

A: Use 0.8 mm or 1.0 mm wheels for thin, precise cuts on small profiles or delicate materials where low cutting force and minimal heat are essential. The 1.2 mm option offers slightly greater durability for medium profiles while still ensuring clean, accurate cuts.Q: Where can these cut off wheels be used in terms of machine compatibility?

A: These wheels are compatible with angle grinders and rotary cut-off machines, supporting both handheld and automatic operations. They fit standard center hole diameters of 16 mm and 22.23 mm, accommodating various metalworking setups.Q: What are the benefits of the double mesh fiber reinforcement in these wheels?

A: The double mesh fiber reinforcement enhances wheel strength and safety, reducing the risk of breakage even at high cutting speeds. This allows for stable, precise cuts and extended wheel lifespan during industrial and professional use.Q: How does compliance with EN12413 and ISO 9001 impact user safety and product reliability?

A: Compliance with EN12413 and ISO 9001 ensures the wheels are manufactured to strict quality and safety standards, offering reliable performance, reduced operating risks, and consistent cutting results in demanding work environments.Q: What process and usage tips ensure optimal results with these thin cut off wheels?

A: Use the wheels at the recommended maximum RPM (up to 13,300) and avoid excessive force. Operate using steady, even pressure for high-speed, precise cuts. For best results, choose appropriate thickness and grit size for the specific material and application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cut off Wheel Category

Plain Cutoff Wheels

Price 8 INR / Piece

Minimum Order Quantity : 25 Pieces

Shape : Round

BladeSize : NA

Coating : NA

Light Duty Reinforced Cutoff Wheels

Price 7 INR / Piece

Minimum Order Quantity : 25 Pieces

Shape : Round

BladeSize : NA

Coating : NA

Industrial Cut off Wheels

Price 200 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Round

Material : Others

BladeSize : 350x2.5x25.4mm, 300x3.2x25.4mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese